I was invited to share about my board game manufacturing experience at the SG Card & Board Game Showcase over the weekend. This is a transcript of my main points.

Thanks for the opportunity to share about my board game manufacturing experience. Before I go into that, I’d like to share a bit about myself to set the context for what comes next.

Firstly, my background is in communications and theology. That’s what I’ve been trained in. How I think is informed by these fields. However, design is a passion that I’ve had the chance to focus on only in the last five years, producing Smol Tok, Mooncake Master, and Chope! The Card Game.

Secondly, I’m not a gamer. I’ve never considered myself to be one. I like to play good games. But I also like to read good books and listen to good music. So although I'm not a gamer, I approach board games and design from a much broader perspective.

Finally, I believe good design can save the world, and bad design can destroy it. Design is important because it impacts people. So we need to design everything better - our policies, housing, transportation, education, supply chains - and of course, our board games.

Starknicked and Origame

To cap off my introduction, I want to introduce the work that I do. I founded Starknicked four years ago and created the Smol Tok universe of facilitation tools. This year, I co-founded Origame to make board games. Both companies start from opposite ends but they have the same goal of bringing people together and building communities.

Smol Tok works by playing with meaning through questions and conversations, which enables players to experience relationship building in a fun way.

Origame creates fun board game experiences like Mooncake Master and Chope! that lead to meaningful realisations about life, with special emphasis on Asian society, culture, and heritage.

Which leads me to this holy trinity of cheap, fast, and great.

Everyone wants to achieve this, not just designers. But if you’re Asian and a designer, you probably want it even more. Unfortunately, you can only achieve one or two in any given project.

2015

The first Smol Tok Basic Deck was manufactured by a printer in Malaysia. At the time, I knew very little about industry standards but a designer friend recommended them on account of their reliability and affordability. Cost was the most important factor to me as I had to sink my own savings into printing a few thousand decks. I continued to release expansion packs over the next two years but was shocked to discover that certain batches of decks were turning yellow.

The printers blamed the weather, their paper suppliers, politics - but they wouldn’t compensate for the defects. I had to write off a few hundred yellowing decks and learn an expensive lesson - there’s always a price to pay for being cheap.

2019

When I co-founded Origame early this year, I knew we had to find a different printer for our first board game, Mooncake Master. Our peers pointed us to a printer in Taiwan that manufactures board games exclusively. We made a pilgrimage there in September, just before Taiwan Original Boardgame EXPO 2019, to understand their processes.

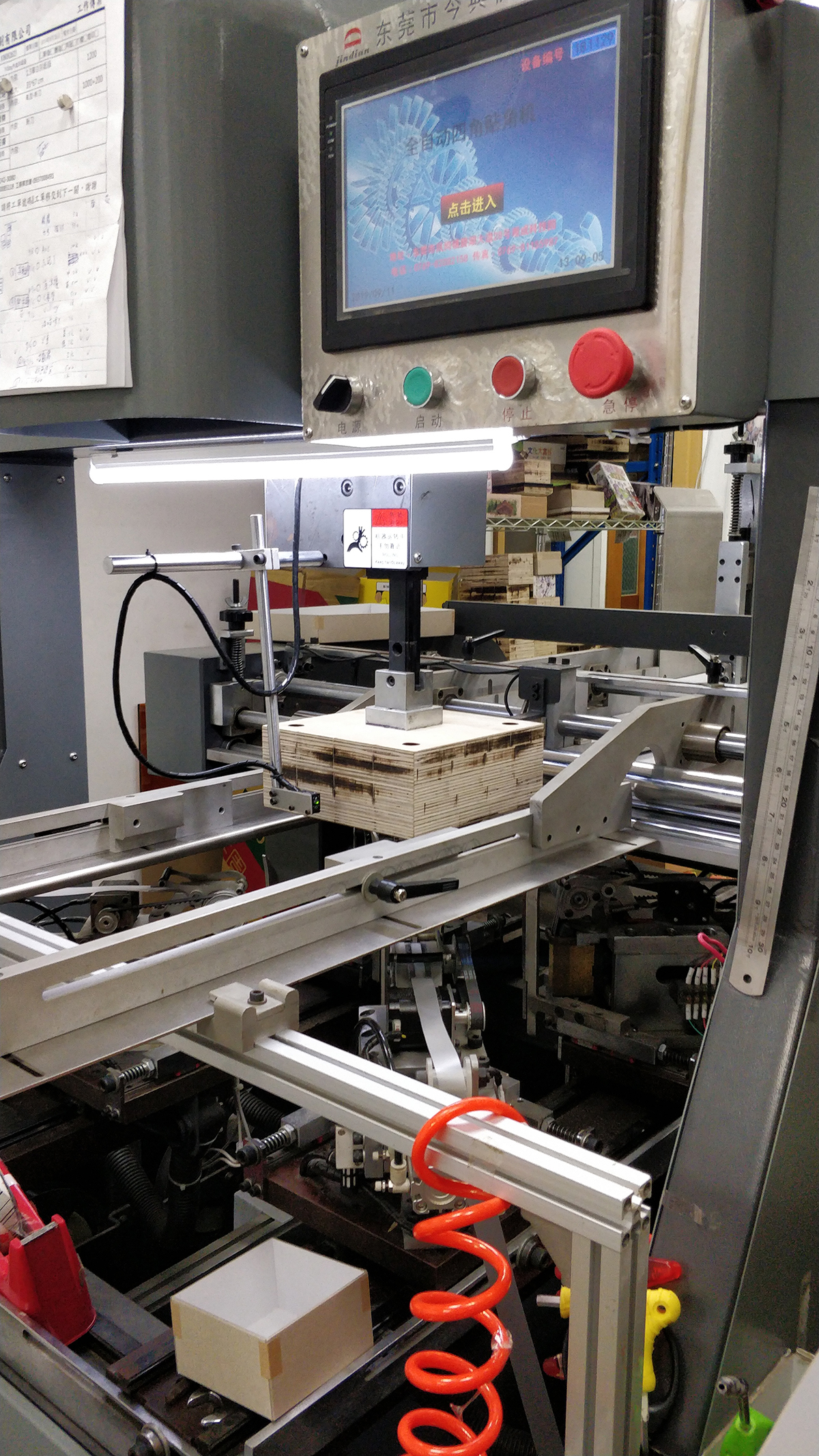

I was surprised at how manual their production line was, with people sitting/standing at machines physically assembling boxes, bundling tokens, or shrink-wrapping cards.

In this factory, machines might prepare the material but people still make the board games. For me, this lends a certain warmth and dignity to what would otherwise be coloured pieces of cardboard and paper.

Their ages and backgrounds varied widely. Some were in uniforms and looked under-aged. But they appeared to be there as whole family units working on the production line. Hokkien tunes blasted on the radio amidst the rattle and hum of the printing and stamping machines.

Communication is something that can always be improved upon. There have been several hiccups and missed deadlines. Having said that, we have a direct line of contact to them on Messenger or Line. They would send photos of updates or colour proofs for us to comment on or approve. It’s no substitute for seeing it in person but we've found that we could rely on their recommendations.

Did I mention that the printers are gamers themselves? The significance of this became clear when we had to choose the linen finish on Mooncake Master. Linen finishes are an important aspect in board game design because they add a textural refinement to the finger-feel when players handle the game components.

The range and detail of their selection is extensive, with hundreds of linen finishes to choose from. These are generally unavailable with other printers who do not specialise in board game manufacturing. We eventually settled on a grid pattern for the cards and tiles in Mooncake Master.

With our current Taiwanese printer, we prioritised quality in the final product. But we’ve had to make allowances for communication breakdowns and delays in the feedback loop. Because their production line is not automated, inefficiencies frequently creep in. You can’t have it all.

Know Your Non-Negotiables

At this point in my design journey, I’ve come to realise that cheap, fast, and great are not absolutes to be achieved but are starting points for us to explore what value, timeliness, and excellence means. Instead of asking printers to deliver cheap, fast, and good, I ask myself questions like these now:

The result is that I’m a lot clearer about my own parameters and tolerances when it comes to issues of cost, speed, and quality in the board games manufacturing process.

This is essential to the work of any designer. Making board games involves creatio ex nihilo, creating something out of nothing. You need to possess a vision of what the final form of the board game will look like before you can produce it. Of course, designs will evolve but at least you'll have a reference point to see where you’re headed. With that in mind, questions like the ones above will help you make better choices in the manufacturing process.

I began my sharing with a focus on printers and understanding how they work. That is only half the equation. I hope the experiences I recounted have sufficiently shifted that focus to the importance of knowing yourself.

To round up my sharing, after producing two board games this year alone, I'm realising the need to design sustainably with waste minimisation in mind right from the start. This entails not just an ecological consideration of what materials are used in producing and packaging our games, such as the justifiable use of paper, plastic, or wood - but also making choices during the development phase to eliminate unnecessary bloat. To me, this just makes business and environmental sense.

I think we can do this better in Origame, and communicate these values clearer. Board games should be a source of fun and meaning, but not at the expense of nature or future generations of board gamers.

What about you? What expectations about value, timeliness, and excellence do you have in the board games manufacturing process?

Comments